LAPROCO

About the lab

The Laboratory of Business Process Management (LAPROCO) was established for the practical teaching of the study programme Process Management and other study programmes at the Faculty of Business and Management. The laboratory is equipped with hardware, software and technical equipment simulating an "intelligent factory", which enables not only practical teaching but also applied research in the field of advanced manufacturing technologies, especially for small and medium-sized enterprises.

Vision and strategy

The dynamic development of advanced systems and technologies is increasingly reflected in all business processes, both production, administrative and service processes. The smart factory, i.e. the interconnection of machines, people and services along the entire value chain, is becoming particularly important in manufacturing companies. In the Business Process Management Lab, students and companies can test new advanced technologies and systems.

Vision

One laboratory - many possibilities

- A centre for digitalisation issues in applied research, especially for SMEs.

- A training model company where future employees will be qualified to deal with digitalization through practical case studies.

- Offering businesses, students and interested parties the opportunity to try out advanced technologies.

- A professional platform for discussion and testing of new technologies and systems.

- Continuing education for managers in the field through individual training programs.

The key areas of the LAPROCO laboratory include the integration of the entire value chain, from the initial idea and design, through product implementation to after-sales service (horizontal integration), as well as the integration of IT with the flow of data from production to corporate IT systems (vertical integration). The "human factor" is also part of the digitalization solution. The lab equipment allows for the exploration of skills and job profiles of the future, as well as ways to use systems (e.g. virtual and augmented reality) to support workers in production or service.

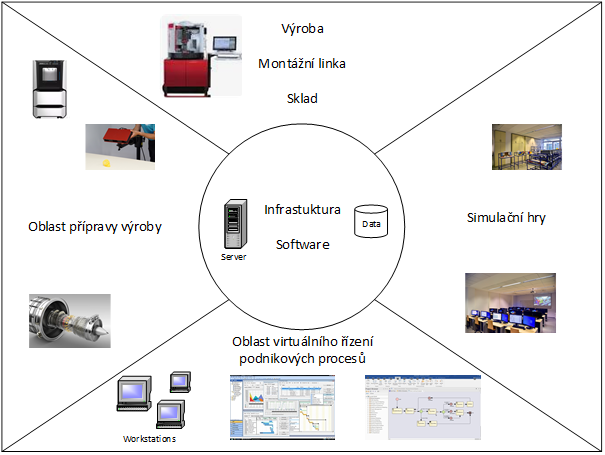

Layout

The Laboratory of Business Process Management is divided into four sections that form the environment for teaching and research. The Development and Production Preparation Laboratory includes technical equipment for teaching and research in the field of business process management (see Figure 1).

Figure 1 Layout of the LAPROCO laboratory

Laboratory equipment

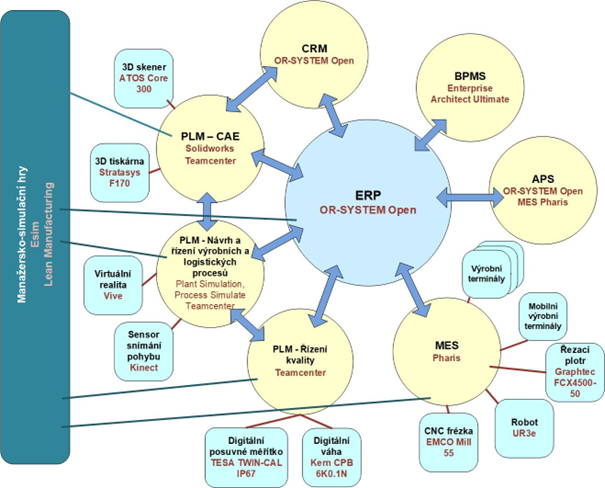

The equipment of the LAPROCO laboratory can be divided into infrastructure, software, hardware and simulation games (see Figure 2).

Figure 2 Overview of systems and equipment

Infrastructure

- Windows server OS

- MS SQL Server 2014 Enterprise

- Virtualization platform/storage

- Independent wi-fi network

- Two computer labs with 33 workstations

Software

-

ERP system - OR SYSTEM Open

-

CRM system - OR SYSTEM Open

-

CAD/CAM system - SOLIDWORKS Premium Edu

-

PLM/PDM - TEAMCENTER

-

PLM - design and management of production and logistics processes - Tecnomatix

-

MES system - Pharis (incl. APS)

-

BPMS - Enterprise Architect Ultimate

Hardware

-

3D Printer - Stratasys F170

-

3D scanner - Atos Core 300 Professional Line

-

Optical motion sensor - Kinect

-

VR Goggles - HTC Vive

-

Stationary manufacturing terminals - Colormetrics P1000 all-in-one PC with RFID chip reader and barcode reader

-

Mobile production terminals - 3 Windows tablets

-

Robot - UR3 collaborative robot (Universal Robots)

-

Plate cutting plotter - Graphtec FCX4500-50

-

Multifunctional thermolite

-

CNC milling machine - ConceptMill 55

-

Digital scale - Kern CPB 6K0.1N | up to 6 kg | 3× display + RS232 / ETH converter

-

Label Printer - Zebra GK420t

-

Digital sliding scale - TESA TWIN-CAL + TESA TLC-BLE transmitter

Simulační hry

-

Soft skills -Esim (economic simulation)

-

Simulation of production and logistics - original production line including warehouse

Examples of projects carried out in the lab

Many bachelor and diploma theses and international student projects have been produced in the laboratory during its existence. Examples of selected theses are given below.

Bachelor theses

Bičan Vladimír. Optimalizace výrobního procesu v zámeckém vinařství - https://www.vut.cz/studenti/zav-prace?zp_id=135034

Chvátal Štěpán. Návrh systému řízení výroby kalových čerpadel - https://www.vut.cz/studenti/zav-prace?zp_id=135033

Machačová Simona. Optimalizace pracoviště tvarování - https://www.vut.cz/studenti/zav-prace?zp_id=135028

Pokorný Robin. Zeštíhlení výroby konektorů s využitím prediktivní simulace - https://www.vut.cz/studenti/zav-prace?zp_id=143084

Slechan Martin. Automatická tvorba dokumentace prostřednictvím parametrizace produktu - https://www.vut.cz/studenti/zav-prace?zp_id=127362

Ťopková Lucie. Návrh systému zásobování nové haly - https://www.vut.cz/studenti/zav-prace?zp_id=127316

Wolker Jakub. Podpora ranních mítinků výroby prostřednictvím digitálního vizualizačního software - https://www.vut.cz/studenti/zav-prace?zp_id=127553

Diploma theses

ČERMÁKOVÁ, Lucie. Příprava výroby modelového podniku. - https://www.vut.cz/studenti/zav-prace/detail/159369

Horák Michal. Modelování výroby komponent zubového čerpadla - https://www.vut.cz/studenti/zav-prace?zp_id=143127

Machačová Simona. Zlepšení procesu lakovny prostřednictvím prediktivní simulace - https://www.vut.cz/studenti/zav-prace?zp_id=152003

Machovec Marek. Návrh podpory řízení zakázky v informačním systému - https://www.vut.cz/studenti/zav-prace?zp_id=152324

Mišková Lucie. Automatizace procesu plateb pomocí RPA - https://www.vut.cz/studenti/zav-prace?zp_id=135030

Wolker Jakub. Návrh reportingu jako podpora rozhodování managementu v oblasti zlepšovacích nápadů - https://www.vut.cz/studenti/zav-prace?zp_id=143149

International student projects

Kateřina Prosecká, Polina Khalturina (VUT v Brně), Lorenz Boruch, Miriam Lutz Rosello (FH Joanneum, University of Applied Sciences Kapfenberg, Rakousko), João Silva, Nuno Pereira (Coimbra Business School ISCAC, Portugalsko) - Sustainable Digital Production in Terms of Lean Management. Euroweek 2022 (téma „Design and Corporate Social Responsibility“)

Jakub Kolník, Polina Khalturina (VUT v Brně), Valeria Rosello (FH Joanneum, University of Applied Sciences Kapfenberg, Rakousko), Theophile Delalée, Tanguy Sergeant (The Technical Institute of The University of Lille, Francie). Personalize It: Production Strategies for Mass Customization. Euroweek 2023 (téma „The Future of Technology and Innovation“)

Vanessa Aparecida Valadares de Sá (Federal Center for Technological Education of Minas Gerais, Department of Civil Engineering), Pedro Henrique Dell'Agnelo Micheluzzi (Federal University of Paraná, Department of Mechanical Engineering) Unigou Remote Academic Internships 2023 (Téma „The Framework of Logistics 4.0“)

Dominika Kuchtová, Jiří Mičánek (VUT v Brně), Arsen Gevorgyan, Kevin Henouille (IUT de Lille, Francie), Abigail Garcia, Katrin Höfler (FH Joanneum, University of Applied Sciences Kapfenberg, Rakousko). Products and Services Engineering in Digital Sustainable Era ... synergy or antagonism? Euroweek 2024 (téma „Dilemmas in the Transition towards a Sustainable Future“)

Creative activity projects carried out in the laboratory

Program Aktion č. 98913 – Product Innovation Planning. Řešitel: Ing. David Schüller, Ph.D., Ing. Zdeňka Videcká, Ph.D. (VUT v Brně), Dipl.Ing. Dr. Wolfram Irsa, CFPIM, CIRM University of Applied Sciences, FH Joanneum, Kapfenberg)